The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Revolutionizing Efficiency: How Bagging Filling Machines Reduce Packaging Costs by Up to 20%

The modern packaging industry is continuously evolving, and one of the most significant advancements comes from bagging filling machines. These innovative systems have transformed how businesses approach efficiency and cost management in their operations. According to recent industry reports, companies incorporating automated bagging filling solutions can reduce packaging costs by up to 20%, a substantial saving that can significantly impact the bottom line.

Furthermore, as the demand for fast and reliable packaging grows, the adoption of these machines is becoming crucial. A report by MarketsandMarkets highlights the increasing necessity for automation, predicting a compound annual growth rate (CAGR) of 5.7% in the packaging machinery market by 2025. As such, the integration of bagging filling machines not only streamlines production processes but also aligns with the industry's shift towards smarter, more resource-efficient operations.

Identifying Packaging Challenges and Their Cost Implications

The packaging industry faces numerous challenges that directly impact operational costs. Identifying these challenges is essential for companies aiming to streamline processes and maintain competitiveness. Issues such as inefficiencies in material usage, labor costs, and supply chain disruptions can significantly increase packaging expenses. By leveraging advanced technologies, such as bagging filling machines, companies can effectively address these challenges.

Bagging filling machines are revolutionizing the way packaging is managed, leading to enhanced efficiency and reduced costs by up to 20%. These machines minimize manual labor and material wastage, ensuring a more controlled and reliable packaging process. The integration of such technologies not only helps businesses save money but also improves their ability to adapt to market changes.

As the packaging sector continues to evolve, companies that proactively tackle their cost implications will set themselves up for long-term success.

Understanding the Mechanisms of Bagging Filling Machines

Bagging filling machines are innovative devices designed to enhance the efficiency of packaging processes across various industries. Understanding their mechanisms reveals how they optimize operations. These machines utilize advanced technologies, such as volumetric or gravimetric filling methods, to accurately dispense products into pre-formed bags. This precision minimizes waste and ensures consistent product weight, essential for maintaining quality standards and adhering to regulatory requirements.

Moreover, the automation integrated into bagging filling machines allows for high-speed operation, significantly increasing output levels. By reducing manual labor, companies can lower operational costs while reallocating workforce efforts to more value-added tasks. The adaptability of these machines also means they can handle a wide range of materials, from powders to granules, making them multifunctional assets in the packaging line. Combined, these factors contribute to a substantial reduction in overall packaging costs, making bagging filling machines a critical investment for businesses aiming to enhance productivity and profitability.

Evaluating the Efficiency Gains from Automation in Packaging

The automation of packaging processes, especially through the use of bagging filling machines, has proven to be a game-changer in enhancing operational efficiency. These machines streamline the packaging workflow by significantly reducing the time required for each filling operation, thus allowing companies to process higher volumes of product simultaneously. Automation not only minimizes human error but also improves consistency in packaging, ensuring that each bag is filled accurately and uniformly, which is crucial for maintaining quality standards.

In addition to speeding up production, bagging filling machines contribute to substantial cost savings. By reducing labor costs, as fewer personnel are required to manage the packing process, companies can allocate their resources more effectively. The efficiency gains from automation also extend to reduced material waste and improved inventory management, as these machines often come equipped with technology that optimizes the use of packaging materials. As a result, businesses can see a reduction in packaging costs by up to 20%, making a compelling case for the adoption of automated solutions in the packaging industry.

Efficiency Gains from Bagging Filling Machines

Calculating the Cost Savings: A Financial Breakdown

The integration of bagging filling machines into production lines has proven to be a game-changer for businesses looking to optimize their packaging processes. A financial breakdown of the associated cost savings reveals how significant reductions in packaging expenses can be achieved. Initially, companies may face a capital investment for these advanced machines; however, the long-term savings often outweigh these upfront costs. Labor expenses are notably decreased as these machines automate operations that would typically require manual labor, leading to a quicker turnaround time and fewer errors.

In addition to labor savings, the efficiency of bagging filling machines translates to reduced material waste. By ensuring precise fill weights and minimizing spillage, businesses can optimize their packaging materials effectively. Furthermore, improved speed means that more products are packaged within the same time frame, ultimately increasing production capacity without additional work hours. By analyzing these factors, it becomes evident how bagging filling machines can contribute to lowering overall packaging costs by as much as 20%, making them a worthy investment for companies aiming to enhance profitability while maintaining high standards of packaging efficiency.

Revolutionizing Efficiency: How Bagging Filling Machines Reduce Packaging Costs by Up to 20% - Calculating the Cost Savings: A Financial Breakdown

| Parameter | Existing Process Cost ($) | Machine Cost ($) | Savings (%) | Annual Savings ($) |

|---|---|---|---|---|

| Material Costs | $50,000 | $40,000 | 20% | $10,000 |

| Labor Costs | $30,000 | $25,000 | 17% | $5,100 |

| Overhead Costs | $20,000 | $18,000 | 10% | $2,000 |

| Maintenance Costs | $15,000 | $12,000 | 20% | $3,000 |

| Total Savings | $115,000 | $95,000 | 18.26% | $20,100 |

Implementing Bagging Filling Machines: Steps for Successful Adoption

Implementing bagging filling machines can significantly streamline packaging processes, making them more efficient and cost-effective. According to a 2022 industry report by Packaging Strategies, companies that switch to automated bagging systems can reduce labor costs by up to 30%, allowing organizations to allocate resources more effectively.

To successfully adopt these machines, businesses should first evaluate their specific needs, identifying the products to be packaged and the desired fill rates. This initial assessment is crucial to select the right machine that aligns with production goals.

Once the appropriate machinery is selected, companies should focus on training staff. A well-trained workforce can maximize the benefits of bagging filling machines, ensuring minimal downtime and high quality in the packaging process. The same report highlighted that comprehensive training programs can enhance operational efficiency by 25%, diminishing the risk of errors during packaging.

Additionally, implementing a routine maintenance schedule is vital to keep machines in optimal condition, thereby sustaining a reduction in packaging costs by up to 20% while extending machine lifespan. By taking these structured steps, businesses can position themselves to thrive in an increasingly competitive market.

Related Posts

-

Unlocking Efficiency in Bagging Filling Processes with Data Driven Strategies

-

The Ultimate Guide to Choosing the Best Industrial Packaging Solutions for Your Business

-

Future Trends in Packaging Systems and Innovative Solutions for Global Buyers

-

Unlocking Efficiency Through Innovative Packaging Systems for Global Supply Chains

-

Crafted to Perfection: China’s Leading Bag Packaging Machine for Global Excellence

-

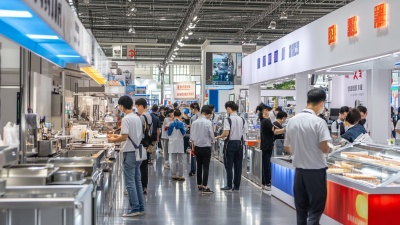

Discover the Success of Bag Sealing Machines at the 137th Canton Fair in Guangzhou