The Duravant family of operating companies serve the food processing, packaging and material handling segments.

What is a Ball Bearing and How Does it Work?

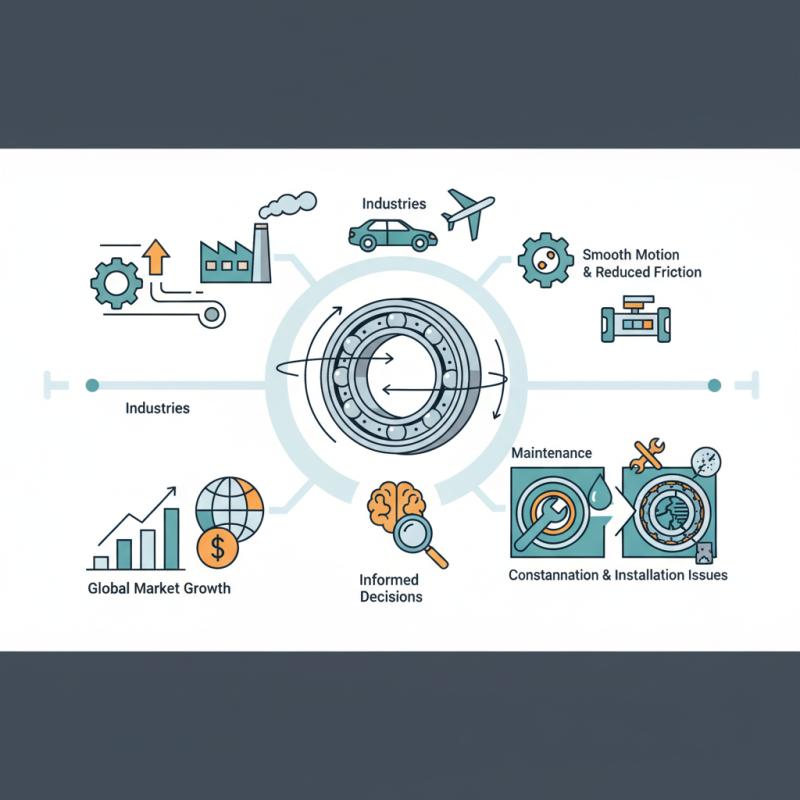

Ball Bearings are vital components found in a myriad of machines. They reduce friction and enable smooth motion. According to a report from Grand View Research, the global bearing market is projected to reach $100 billion by 2025, with ball bearings accounting for a substantial portion. This underscores their importance in various industries, including automotive, aerospace, and manufacturing.

Understanding how ball bearings work can enhance their application efficiency. These precision-engineered devices allow machinery to operate smoothly, significantly extending mechanical lifespan. Despite their crucial role, many users overlook the need for regular maintenance. Effectively maintaining ball bearings can prevent failures and enhance performance.

Moreover, while ball bearings are designed for durability, they are not impervious. Factors like contamination and improper installation can lead to issues. Misalignment or insufficient lubrication can have severe consequences. As users become more aware of these pitfalls, they can make more informed decisions to ensure optimal performance and longevity of their machinery.

What is a Ball Bearing?

A ball bearing is a crucial component in many machines. It reduces friction between moving parts, allowing for smoother operation. These bearings consist of balls placed between two metal rings. The design enables efficient load distribution and minimizes wear. According to industry data, ball bearings can decrease energy consumption by up to 30%. This efficiency is vital in manufacturing settings.

The materials used in ball bearings often include steel or ceramic. The choice of material affects the bearing's performance and lifespan. Steel bearings tend to be more durable but are susceptible to corrosion. Ceramic bearings, while lighter and resistant to wear, can be more brittle. Some studies show that about 20% of bearing failures result from improper lubrication. Regular maintenance practices can prevent these issues.

Ball bearings are widely utilized in various sectors, from automotive to aerospace. Yet, installation and alignment are critical. Misalignment can lead to premature failure. It's essential to ensure that bearings are handled with care during installation. Ignoring these details may cost time and money in the long run. Striking a balance between cost and quality is always a challenge for engineers.

The Components of a Ball Bearing Explained

Ball bearings play a crucial role in machinery. They reduce friction between moving parts. Understanding their components helps grasp their function better. A typical ball bearing consists of an inner ring, outer ring, balls, and a retainer. Each part needs precision engineering. The balls, usually made of steel or ceramic, help to support the load.

The inner ring rotates with the shaft. The outer ring remains stationary. The balls move in raceways between these rings, allowing for smooth motion. Reports indicate that ball bearings enhance operational efficiency by up to 30%. Yet, many overlook the importance of maintenance. Dirt and wear can impair performance over time.

Retainers, or cages, keep the balls evenly spaced. They allow for consistent load distribution. This is critical in high-speed applications. According to industry data, improper installation can lead to reduced lifespan. Awareness of these components is essential for overall machinery reliability. Understanding ball bearings is not just for engineers. Proper knowledge can save time and costs in various applications.

How Ball Bearings Reduce Friction and Wear

Ball bearings are crucial in reducing friction and wear in various machinery. They achieve this by allowing smooth rotation between moving parts. When a load is applied, ball bearings distribute the weight evenly. This minimizes direct contact between surfaces, reducing the potential for wear and increasing the lifespan of components.

According to a report from the American Society of Mechanical Engineers, ball bearings can decrease friction by up to 90%. This remarkable efficiency is critical in applications ranging from electric motors to automotive engines. It’s interesting to note that even a small misalignment can increase friction significantly. This underlines the importance of precise installation and maintenance.

While ball bearings are effective, they aren't without flaws. For instance, contamination can lead to premature failure. Dirt or moisture can enter the bearing unit, causing damage. This emphasizes the need for regular inspections and proper sealing. Engineers need to be mindful of these factors to ensure optimal performance.

Types of Ball Bearings and Their Applications

Ball bearings are crucial components in various machinery. They reduce friction, enabling smoother motion. There are several types of ball bearings, each designed for specific applications. The most common types include deep groove, angular contact, and self-aligning bearings. According to a recent market analysis, the global ball bearing market is expected to reach $80 billion by 2027. This growth highlights their importance in industries ranging from automotive to aerospace.

Deep groove ball bearings are versatile. They can handle radial and axial loads. These bearings are typically used in electric motors and household appliances. Alternatively, angular contact bearings are designed for high-speed applications. They allow for higher axial loads compared to deep groove bearings. Industries that rely on high precision, like aerospace and robotics, often prefer these.

Self-aligning ball bearings, on the other hand, accommodate misalignment. This feature makes them ideal for applications in conveyor systems and heavy machinery. However, it's essential to choose the right bearing type for specific operational conditions. Not considering operational load and speed can lead to premature failure. Each bearing type has its strengths and weaknesses, further complicating selection. Proper research and analysis are vital to avoid costly mistakes in application.

Ball Bearing Types and Their Applications

The Importance of Proper Maintenance for Ball Bearings

Proper maintenance of ball bearings is crucial for their longevity and performance. According to a report by the National Institute for Standards and Technology, improper maintenance can reduce bearing life by up to 90%. This staggering figure highlights how critical it is to conduct regular inspections. A small amount of dirt can cause significant wear over time.

Greasing is one aspect that should not be overlooked. Many technicians recommend that bearings be re-greased every 500 to 1,000 operational hours. Failing to do so can lead to overheating and premature failure. Visual inspections are important too. Look for signs of rust or discoloration, which can indicate a problem.

Even the best bearings will fail if not cared for. It's essential to have a comprehensive maintenance plan. Shock loads and vibrations can cause misalignment. This misalignment can lead to uneven wear. Monitoring these factors can extend the life of bearings significantly. Hence, investing time in proper maintenance pays off in the long run.