The Duravant family of operating companies serve the food processing, packaging and material handling segments.

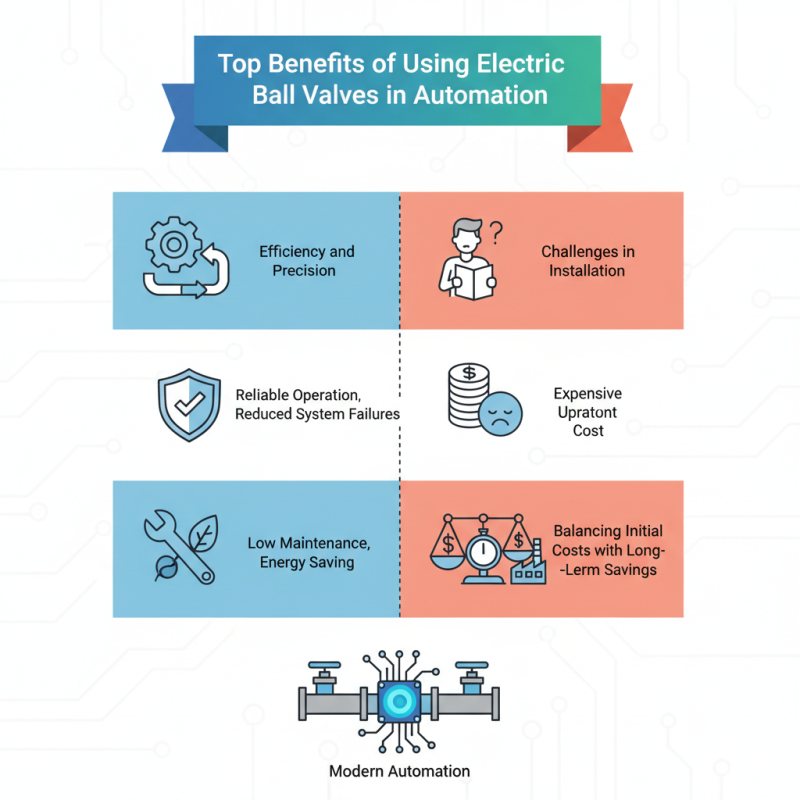

Top Benefits of Using Electric Ball Valves in Automation?

In recent years, the use of Electric Ball Valves in automation has grown significantly. According to industry expert James Smith, “Electric Ball Valves offer unmatched efficiency and precision in flow control.” These valves are essential for various applications in sectors like manufacturing and energy.

Electric Ball Valves provide precise control. They ensure reliable operation, reducing system failures. Their low maintenance needs are appealing, yet some users report challenges in installation. Additionally, these valves can be expensive upfront, which may prompt hesitation for smaller businesses.

Efficiency is one of their key benefits. They can save energy and reduce operating costs over time. However, users need to fully understand their systems’ requirements. Balancing initial costs with long-term savings is critical. Electric Ball Valves play a vital role in modern automation, yet careful consideration is necessary to maximize their potential.

Key Advantages of Electric Ball Valves in Automated Systems

Electric ball valves are gaining traction in automation systems due to their numerous benefits. One of the key advantages is precision control. According to a recent industry report, automated systems implementing electric valves show accuracy improvements of up to 30%. This can lead to better process stability and less waste. Accuracy means less energy consumption, which is crucial in today’s economy.

Another benefit is ease of integration. Electric ball valves can easily connect with various control systems. Studies indicate that integrating these valves reduces installation time by about 25%. However, some engineers find the initial programming settings can be challenging. This complexity might deter some users from making the switch, even if the long-term benefits are clear.

Additionally, maintenance is simpler with electric models. Data reveals that electric ball valves require less frequent servicing compared to manual alternatives. Maintenance costs can drop significantly. Despite this, users must remain vigilant about potential failures, as even small malfunctions can disrupt entire systems. Balancing convenience and reliability is critical for optimized performance in automated environments.

Improved Precision and Control in Fluid Management

Electric ball valves play a significant role in automation. They enhance precision and control in fluid management. These valves respond swiftly to changes, providing better regulation of flow rates. This improves system efficiency and reliability.

When integrating electric ball valves, consider their response time. A quicker response means better accuracy. Fluid dynamics can be unpredictable. Therefore, having a responsive valve makes a difference. Automation systems benefit by minimizing delays in process adjustments.

Tips: Regular maintenance of the valves ensures long-term efficiency. Monitor the system for any irregularities. This can help avoid major failures down the line. Another tip is to calibrate the valves periodically for precise control. Even slight deviations can lead to issues.

Enhanced Energy Efficiency for Sustainable Operations

Electric ball valves are becoming a game-changer in automation. One standout feature is their energy efficiency. They consume less power than traditional valves, making operations more sustainable. This reduction can lead to significant cost savings over time. By minimizing energy waste, facilities can reduce their overall carbon footprint.

Moreover, these valves offer precise control. They can quickly respond to changes in pressure or temperature. This responsiveness helps maintain optimal conditions within a system. However, the initial installation can be challenging. Proper integration with existing systems requires careful planning. It’s crucial to evaluate whether the upgrade will deliver expected benefits.

Maintenance is another aspect to consider. While electric ball valves often require less upkeep than other types, they are not maintenance-free. Regular checks are still necessary to ensure long-term performance. Users should remain vigilant about wear and tear. Balancing the benefits of energy efficiency with these challenges can lead to more informed decisions in automation.

Top Benefits of Using Electric Ball Valves in Automation

This chart illustrates the key benefits of using electric ball valves in automation processes, highlighting enhanced energy efficiency as a crucial aspect for sustainable operations.

Reduced Maintenance Costs Compared to Manual Valves

Electric ball valves offer significant advantages in automation, particularly when it comes to maintenance costs. Unlike manual valves, which often require regular inspection and adjustments, electric valves operate with minimal human intervention. This autonomy can lead to substantial savings on labor and repair expenses. Fewer moving parts result in less wear and tear, further prolonging the valves' lifespan.

Additionally, the precision of electric ball valves minimizes the chances of leaks or failures. Regular manual valve operation can introduce human error, leading to costly malfunctions. However, with electric valves, the consistent performance reduces reliance on manpower. Regular maintenance still exists, but it's less frequent and often less intensive.

While the initial investment may be higher for electric ball valves, the long-term savings are noteworthy. It's crucial to assess your specific needs. Some facilities may still find manual valves more suitable for their operations. But, as automation trends grow, electric options are proving to be a remarkable choice for efficiency and reduced costs. Consider your current system carefully before making a switch.

Seamless Integration with Modern Automation Technologies

Electric ball valves are becoming essential in automation systems due to their seamless integration capabilities. Industry reports indicate that over 65% of automated processes are adapting to smart technologies. These valves interact smoothly with control systems, enhancing operational efficiency. They can connect with various sensors and controllers, facilitating instant adjustments.

The precision of electric ball valves supports high performance in processes. According to recent findings, systems leveraging advanced valve technology experience a 20% reduction in energy consumption. This leads to lower operational costs. However, the initial investment in such technologies may raise concerns for some companies. Long-term savings and efficiency gains often outweigh these initial costs.

Furthermore, the data shows that improper integration can cause disruptions. Many users report challenges with compatibility among different automation components. This highlights the importance of thorough planning and testing before implementation. While electric ball valves present clear advantages, companies must remain vigilant about potential integration issues. Investing in staff training could significantly improve outcomes in the automation landscape. By understanding the technology, organizations can maximize the benefits of electric ball valves.