The Duravant family of operating companies serve the food processing, packaging and material handling segments.

How to Choose the Best Flexible Packaging Film for Your Needs?

Choosing the right Flexible Packaging Film can greatly impact product quality and shelf life. According to industry expert John Smith, “The right film can make or break your packaging strategy.” In a market with diverse needs, selecting the ideal film requires careful consideration.

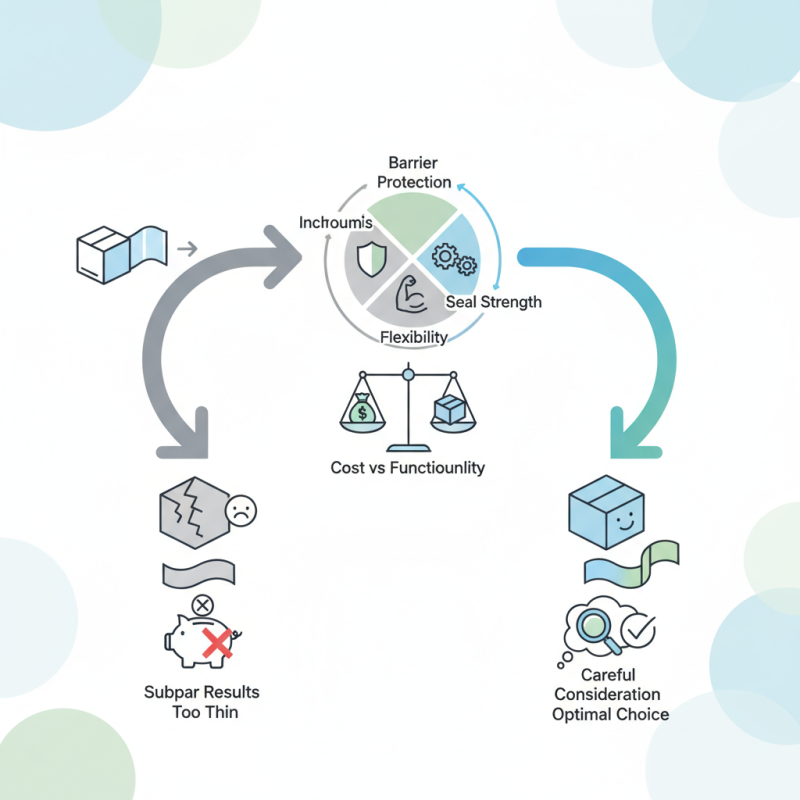

While many may overlook essential details, understanding the specific properties of Flexible Packaging Film is crucial. Different films offer varying levels of barrier protection, flexibility, and seal strength. It's a balancing act between cost and functionality. Brands often find themselves grappling with these choices.

Many choose based on price alone. This can lead to subpar results. A film that is too thin may compromise product integrity. Alternatively, excessive thickness can inflate costs unnecessarily. It's vital to evaluate what truly matters for your unique needs. Reflecting on these aspects can lead to better decisions in Flexible Packaging Film selection.

Understanding the Types of Flexible Packaging Films Available

Flexible packaging films come in various types, each suited for different applications. Common options include polyethylene, polypropylene, and metalized films. According to a recent report by Smithers Pira, the global flexible packaging market was valued at over $250 billion in 2022 and is projected to grow steadily. This growth underscores the importance of selecting the right film type for specific needs.

Polyethylene films are often favored for their moisture-resistant properties. They are lightweight and recyclable. Polypropylene films provide a higher clarity and are typically used for food packaging. Despite their advantages, some manufacturers struggle with the film's susceptibility to low temperatures. Metalized films offer excellent barrier properties and are ideal for extending shelf life. However, they can be more expensive, which might not be feasible for all budgets.

Understanding these film types can help businesses make informed decisions. A well-timed investment could increase competitiveness. However, many companies overlook the importance of proper testing and evaluation. Relying solely on supplier claims may lead to suboptimal choices. Continuously analyzing and adapting to changing market demands can lead to better outcomes.

Evaluating the Key Properties of Flexible Packaging Films

Choosing the right flexible packaging film involves understanding its key properties. Thickness is one important factor. Thinner films may save costs but can reduce durability. A thicker film could enhance protection but increases weight and might affect shipping costs.

Another crucial property is barrier effectiveness. Films must keep out moisture, air, and light, depending on the product. A good film can preserve freshness. However, packaging should be evaluated for specific needs. Not every film performs equally across all environments.

Flexibility is also vital. The film should conform to various shapes and sizes. This adaptability can impact production efficiency. But it requires careful testing. Each type of film has its pros and cons. Evaluate what matters most for your product.

Assessing Compatibility with Your Product and Industry Standards

When selecting flexible packaging film, compatibility with your product is crucial. Understand your product’s characteristics. Consider factors like moisture, light sensitivity, and temperature. These aspects influence how well the packaging protects the contents. For example, perishable items require barrier films to keep them fresh.

Tips: Look for films designed for specific product types. Test samples with your product before making a decision. Ensure the film doesn’t react negatively with the contents.

Adhere to industry standards as well. Different sectors have unique regulations. Food packaging often demands compliance with health and safety guidelines. Cosmetic products might require eco-friendly materials. Striking a balance between durability and compliance can be tricky.

Tips: Research industry standards applicable to your product. Document any compliance tests performed on the packaging. This practice can help avoid costly mistakes later.

Flexible Packaging Film Properties Comparison

Considering Environmental Impact and Sustainability Factors

When selecting flexible packaging film, consider its environmental impact. It’s essential to assess materials used. Many films are made from polymers that take years to decompose. Biodegradable options are available but often come with trade-offs in durability or cost. These films can sometimes have different shelf lives, affecting product longevity.

Sustainability also involves sourcing. Films made from recycled materials can reduce waste. However, the quality might not match virgin materials. Evaluating the entire lifecycle is crucial. This includes production processes and energy consumed during manufacturing. Are these films recyclable? Look for certifications that confirm sustainability claims, but be cautious. Not all claims are backed by solid data.

Lastly, consumer perception matters. More users demand eco-friendly packaging. This pressure can drive development. Yet, ensuring that quality and performance are maintained is vital. In some cases, switching to greener options may result in a higher cost for both producers and consumers. Balancing sustainability goals with practical needs remains a challenge in the flexible packaging industry.

Determining Cost-Effectiveness and Supply Chain Logistics

When selecting flexible packaging film, cost-effectiveness is key. Pricing can vary widely. Materials, thickness, and custom features all impact the cost. Balancing quality and budget is vital. Often, cheaper options compromise durability. This can lead to increased waste and higher shipping costs.

Supply chain logistics also play a role in your choice. Efficient packaging reduces transport time. Consider the size and weight of your packaging. Heavy or bulky films can inflate shipping expenses. Also, think about production timelines. Some materials require longer lead times. Delays can disrupt your entire supply chain. Mistakes here can hurt relationships with suppliers and customers.

Sustainability is another factor to ponder. Biodegradable options may be costlier upfront but could save money in waste management. Analyze your long-term goals. Can you afford to invest in eco-friendly solutions now? Poor choices can lead to future regrets. Reflecting on these elements will guide you to a more informed decision.