The Duravant family of operating companies serve the food processing, packaging and material handling segments.

How to Choose the Right Bag Packaging Machine for Your Needs?

Choosing the right bag packaging machine can be overwhelming. Different products and industries require specific features. Expert John McCarthy, a leader in packaging technology, states, "The efficiency of your packaging line depends heavily on the machine you choose." This underscores the importance of making an informed decision.

When selecting a bag packaging machine, consider your product's characteristics. Think about size, weight, and material. Small adjustments can greatly impact the machine's performance. It’s crucial to assess your production needs. What speed do you require? Could you scale up in the future? These questions demand serious thought.

Remember that no machine is perfect. Some designs may limit flexibility. You might face difficulties with changeovers. It's essential to weigh the pros and cons of each option. Invest time to research and compare different machines. In the long run, the right choice will enhance your productivity and efficiency. A bag packaging machine should fit like a glove for your unique requirements.

Understanding Your Packaging Requirements and Workflow

When selecting a bag packaging machine, understanding your packaging requirements and workflow is key. Start by evaluating the types of products you will package. Different machines cater to various product sizes and shapes. If your products vary widely, you might need a more versatile solution.

Consider your production volume. Will you operate on a small scale or require high-speed output? This impacts the speed and efficiency of the machine you choose. Think about your workspace too. A compact machine may be essential if space is limited.

Tip: Always analyze the entire packaging process. Identify bottlenecks or areas needing improvement. Sometimes, a machine that seems ideal may not integrate well with existing workflows.

Also, engage with operators to gather their insights. They often know what works and what doesn't.

Another crucial aspect is maintenance. Machines require regular upkeep. Research how easy it is to clean and service the chosen model. A machine that is hard to maintain can lead to unexpected downtime and increased costs.

Tip: Document your requirements clearly. This makes it easier to compare different options later. Don't rush the decision; a choice made in haste often leads to regret. Reflect on the long-term impact of your investment. Choose wisely to ensure your packaging process runs smoothly.

Evaluating Different Types of Bag Packaging Machines Available

When evaluating different types of bag packaging machines, it’s essential to understand the specific needs of your operation. There are several options available, including vertical and horizontal bagging machines. Vertical machines are often best for powders and granular products. Their compact design makes them suitable for limited spaces. On the other hand, horizontal machines handle larger, bulk items more efficiently.

Consider the material of the bags you’ll be using. Some machines handle plastic better, while others are designed for paper. Additionally, pay attention to the machine’s speed. A faster machine may increase production, but it can also lead to more errors.

**Tips:** Assess your production volume carefully. A machine too fast for your needs may waste resources. Moreover, think about the machine's accessibility for maintenance. If it’s hard to reach, downtime might increase. Always research potential limitations. Not every machine will fit every type of bag or product. Be flexible in your choice and ready to reassess your options regularly.

Comparative Analysis of Bag Packaging Machine Types

Key Features and Specifications to Consider for Efficiency

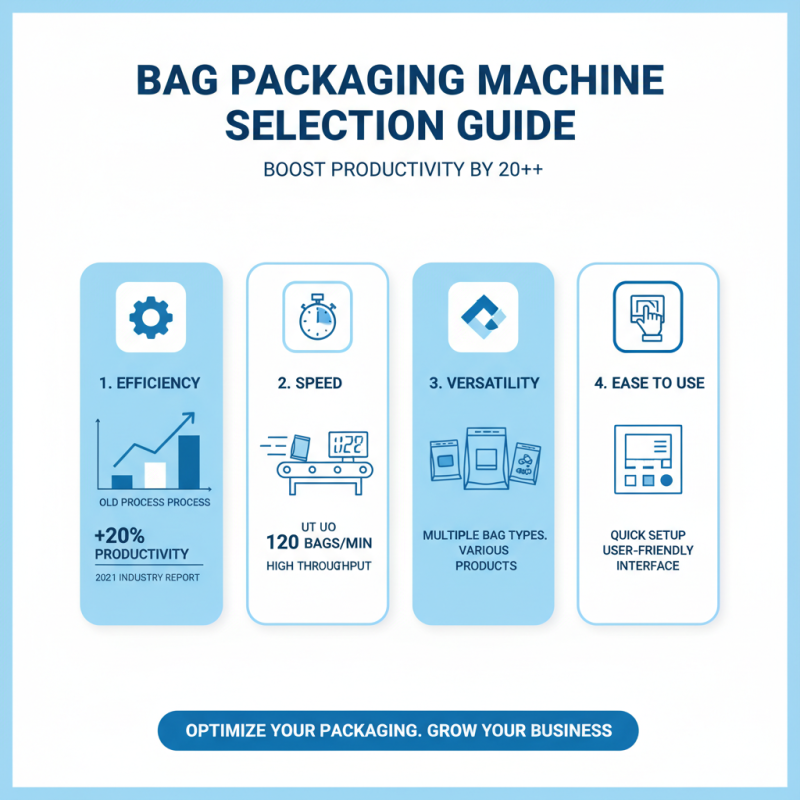

Selecting the right bag packaging machine involves understanding key features and specifications. Efficiency is crucial. A 2021 industry report highlights that companies optimizing their packaging processes can increase productivity by 20% or more. You must consider speed, versatility, and ease of use.

Speed is vital for production lines. Machines can vary in output, ranging from 20 to over 100 bags per minute. But keep in mind, higher speed does not always mean better quality. Your process could suffer if the machine compromises on the precision of seals and fills. Versatility matters, too. Machines that handle multiple bag types can save costs.

Design considerations are also important. User-friendly interfaces streamline operations. Some operators feel overwhelmed by complicated settings. Simple controls enhance efficiency and reduce training time. Ultimately, finding a balance between these features can enhance your production. A mismatched machine can lead to inefficiencies and increased downtime. So, carefully analyze your needs before investing.

Assessing Cost-Effectiveness and Return on Investment

When choosing a bag packaging machine, cost-effectiveness is key. Businesses need to analyze initial costs against potential savings. Consider the machine's efficiency and maintenance costs over time. A machine might seem expensive but can save money in labor and materials. Evaluate how quickly the investment can pay off.

Tips: Start by calculating your current packaging expenses. Compare them with the proposed machine's operation costs. Look for machines that offer energy-saving features. These can significantly reduce your bills. Understand that lower-priced machines might lack durability. This could lead to more repairs and downtime.

Assessing return on investment involves analyzing production speed. A fast machine can increase output and meet demand. However, remember that rapid production may not always ensure quality. Quality control should never take a back seat. Invest time to train staff properly. This can enhance both efficiency and quality, ultimately affecting your bottom line.

Maintenance and Support: Ensuring Longevity of Your Packaging Machine

Maintaining a bag packaging machine is crucial for its longevity. Regular maintenance can extend the life of the equipment and enhance production efficiency. A study from the Packaging Machinery Manufacturers Institute revealed that preventive maintenance can reduce machine downtime by 30%. Proper lubrication, timely inspections, and replacing worn parts are essential tasks. Ignoring these can lead to costly repairs.

Support is another critical aspect of a packaging machine's lifespan. Operators must be trained to handle basic troubleshooting. Statistics show that 25% of operational failures result from human error. Therefore, training programs are vital. Remote support options can also significantly decrease response times during issues.

In some cases, businesses overlook asking for technical support. This can stem from a lack of awareness about available resources. It’s important to track and document machine performance. Regular checks can highlight potential issues before they escalate. Neglect in these areas may cause not just financial losses but also affect product quality. Taking care of your packaging machine is not just smart; it’s essential.

Related Posts

-

Future of Industrial Filling Machines Market Analysis for Global Buyers in 2025

-

7 Key Insights for Sourcing the Best Industrial Packaging Solutions Globally

-

Craftsmanship in Every Detail: Elevating Global Standards with the Best Packaging Machine from China

-

Crafted to Perfection: China’s Leading Bag Packaging Machine for Global Excellence

-

Innovative Chinese Manufacturing Driving Global Adoption of Premier Industrial Packaging Solutions

-

Elevating Global Standards: How China's Best Industrial Packaging Machines Redefine Quality and Trust