The Duravant family of operating companies serve the food processing, packaging and material handling segments.

What is a Damper Actuator and How Does it Work?

A Damper Actuator plays a crucial role in HVAC systems. It aids in controlling airflow within ducts and rooms. This device is integral to maintaining comfort in indoor spaces.

Understanding how a damper actuator functions can seem complex. It uses signals from the HVAC system to adjust dampers. The actuator opens or closes dampers based on specific needs. This involves responding to changes in temperature or air pressure. However, there can be challenges in ensuring accurate response times.

Sometimes, damper actuators do not operate as efficiently as they should. Regular maintenance can help address these issues. Understanding the mechanics of damper actuators can lead to better energy management. This insight can also improve overall indoor air quality. Exploring these devices reveals the balance between comfort and efficiency.

What is a Damper Actuator? Definition and Key Components

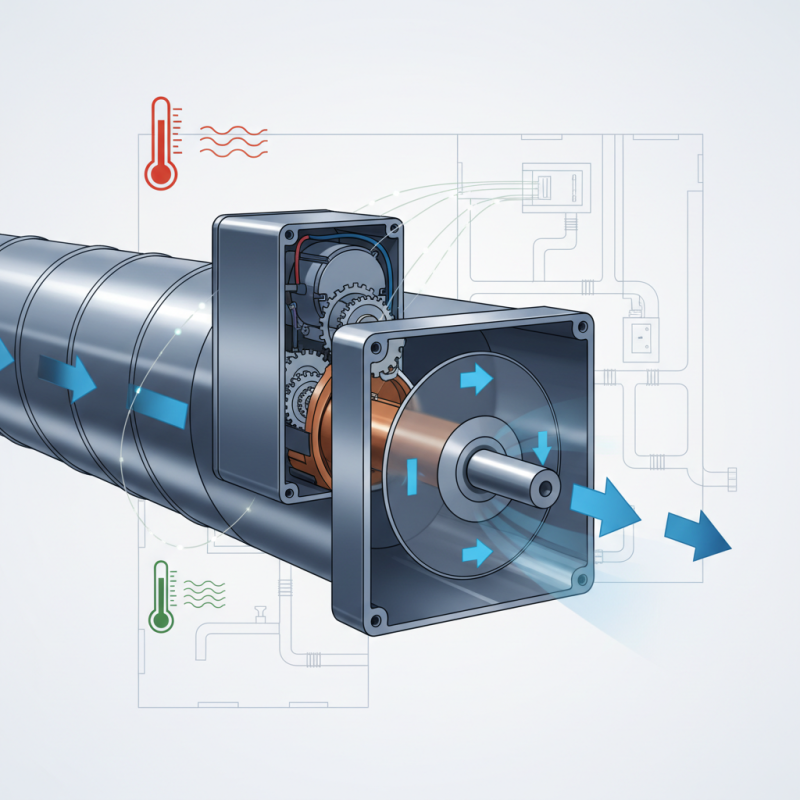

A damper actuator is a vital component in HVAC systems. It controls the airflow and temperature by adjusting the position of dampers. These devices can be electric, pneumatic, or hydraulic. Each type has unique benefits, depending on the system requirements.

Key components of a damper actuator include the actuator body, motor, and linkages. The actuator body houses the motor, which drives the damper blades. Linkages connect the actuator to the dampers, translating the motor’s movement into blade adjustment. Industry reports show that well-designed actuators can improve system efficiency by up to 30%.

Tips for maintaining a damper actuator include regular checks for wear and ensuring the motor operates smoothly. Loose linkages can lead to improper damper operation. Occasionally, inspect the connections to avoid airflow issues. Remember, even minor adjustments can impact system performance significantly. Avoid neglecting routine maintenance, as it can lead to larger, costly problems down the line.

Types of Damper Actuators: Electric, Pneumatic, and Hydraulic

Damper actuators play a crucial role in regulating airflow in ventilation systems. There are three main types: electric, pneumatic, and hydraulic. Each type has unique features and applications.

Electric damper actuators are widely used for their precision. They can be easily integrated into control systems. However, they may require regular maintenance.

Pneumatic actuators, on the other hand, use compressed air and are robust. They excel in high-force applications but are susceptible to pressure fluctuations. Their complexity can lead to potential errors.

Hydraulic actuators are powerful. They are suitable for large dampers in industrial settings. Yet, they often need a hydraulic fluid reservoir, which can complicate installation. Each actuator type has its pros and cons. Understanding these options is vital for selecting the right one for specific needs.

How Damper Actuators Function: The Mechanisms Behind Operation

Damper actuators play a critical role in regulating airflow in HVAC systems. They control how much air is distributed in a building. The actuator mechanically adjusts dampers based on signals from the control system. This adjustment ensures optimal airflow and energy efficiency. Reports indicate that properly functioning dampers can improve system efficiency by up to 30%.

The mechanism behind damper actuators is fascinating. Many use electric or pneumatic power to position the damper blades. Electric models often have motors that rotate the blades, while pneumatic versions rely on air pressure. It’s important to note that if these actuators malfunction, it can lead to poor air distribution. In some cases, this inefficiency can raise energy costs by 20% or more.

Feedback mechanisms are also essential. Sensors monitor the damper position and airflow. These sensors provide real-time data to the control system. Any discrepancies can result in suboptimal performance. It shows that even small mechanical failures can lead to significant inefficiencies. Monitoring these systems regularly is crucial to maintaining their effectiveness.

Applications of Damper Actuators in HVAC and Industrial Systems

Damper actuators play a crucial role in HVAC and industrial systems. They control the airflow by adjusting dampers in ventilation systems. This ensures efficient heating, cooling, and air quality management. Without these actuators, buildings can face discomfort and energy waste. Correct installation is vital for optimal performance.

In industrial settings, damper actuators help regulate processes involving air or gas flows. They can manage exhaust systems and maintain safety protocols. A well-functioning actuator prevents environmental hazards. Improper calibration may lead to inefficiencies. Small adjustments can create significant differences in energy usage.

Tips: Regular maintenance is essential. Check the actuator regularly for wear and tear. Replace any faulty components immediately. Ensure proper alignment with dampers for best results. A little effort can save on energy bills in the long run.

What is a Damper Actuator and How Does it Work? - Applications of Damper Actuators in HVAC and Industrial Systems

| Application Area | Function | Type of Actuator | Control Method | Energy Source |

|---|---|---|---|---|

| HVAC Systems | Regulates airflow and temperature | Electric | Automatic | Electricity |

| Industrial Processes | Controls the flow of gases and particulates | Pneumatic | Manual or Automatic | Compressed Air |

| Commercial Buildings | Optimizes ventilation systems | Motorized | Automated by Building Management Systems | Electricity |

| Power Plants | Regulates exhaust and combustion air | Hydraulic | Automatic | Hydraulic Fluid |

Key Performance Indicators and Efficiency Metrics for Damper Actuators

Damper actuators play a crucial role in HVAC systems by regulating airflow. Their efficiency directly impacts energy consumption and indoor air quality. Key performance indicators (KPIs) for damper actuators include response time, positioning accuracy, and power consumption. Data from industry studies indicate that a well-calibrated actuator can improve system efficiency by up to 25%.

Monitoring positioning accuracy is essential. Small deviations can lead to significant airflow issues. A positioning error of just 5% can decrease system effectiveness. This often gets overlooked in less rigorous systems. Proper testing and calibration are vital for maintaining performance standards.

**Tips:** Regularly check actuator settings. Even slight changes can affect efficiency. Aim for regular maintenance schedules to prevent performance lapses. Stay informed about advancements in actuator technology. They can provide significant energy savings over time. Balancing efficiency with accuracy is the key challenge for many facilities. Reflect on your current system setup; it might need refinement.