The Duravant family of operating companies serve the food processing, packaging and material handling segments.

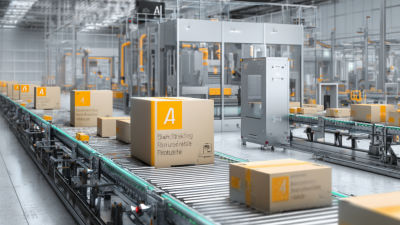

The Future of Automated Packaging: How AI Is Revolutionizing Efficiency and Sustainability in Supply Chains

As we navigate through a rapidly evolving technological landscape, the future of automated packaging stands at the forefront of innovation, poised to transform supply chains with unparalleled efficiency and sustainability. Recent studies predict that the global market for automated packaging will reach $62.2 billion by 2028, driven by the increasing demand for smart packaging solutions and AI integration.

With the advent of advanced artificial intelligence systems, companies are now able to optimize their packaging processes, reducing waste by up to 30% and improving operational efficiency by as much as 50%. Furthermore, Automated Packaging systems are not only enhancing productivity but also aligning with sustainability goals, as they utilize eco-friendly materials and minimize resource consumption.

This confluence of automation and intelligence is fostering a new era in supply chain management, making it imperative for industry players to embrace innovative solutions to stay competitive.

The Role of AI in Enhancing Efficiency in Automated Packaging Solutions

The integration of artificial intelligence in

automated packaging solutions

is set to dramatically enhance efficiency within supply chains.

As businesses strive for optimal productivity, the application of AI technologies allows for

real-time data analysis, predictive maintenance,

and streamlined operations. This transition not only reduces

labor costs but also minimizes human error, thereby increasing overall output and ensuring that

packaging processes are both fast and reliable.

In tandem with this technological shift, the market for

contract lifecycle management software

is experiencing significant growth, estimated to reach

$1.1 billion in 2024. With a

projected compound annual growth rate (CAGR) of 12.9% from 2025 to

2034, driven by the rising demand for regulatory compliance, digital transformation, and automation,

companies are recognizing the necessity of advanced software solutions. These tools not only

facilitate contract management but also provide insights that enhance decision-making processes,

ultimately contributing to a more efficient and sustainable supply chain.

Impact of AI on Waste Reduction and Sustainability in Supply Chains

The integration of AI in automated packaging is transforming supply chains, particularly in terms of waste reduction and sustainability. According to a recent report by McKinsey, the adoption of AI technologies can potentially reduce supply chain waste by 15% to 25%, leading to not only cost savings but also substantial environmental benefits. By harnessing predictive analytics, companies can anticipate demand more accurately, reducing overproduction and excess packaging that typically ends up in landfills.

One key area where AI excels is optimizing packaging materials. Research from the Smithers Pira suggests that using AI-driven algorithms in packaging design can lead to a 20% reduction in material usage while maintaining product protection. This shift not only minimizes waste but also lowers carbon footprints associated with production and transport. For organizations aiming to enhance their sustainability efforts, leveraging AI for better packaging decisions is a game-changer.

**Tips for Implementing AI in Packaging:**

1. Invest in AI technology that can analyze historical sales data to predict future trends, ensuring that packaging aligns closely with actual demand.

2. Collaborate with packaging suppliers who are versed in sustainable practices, using AI to assess and choose the most eco-friendly materials available.

3. Regularly review and adjust packaging strategies based on AI insights to continually improve waste management and sustainability metrics.

Current Market Trends: Growth of Automated Packaging Technologies Driven by AI

The automated packaging industry is witnessing robust growth, largely driven by advancements in artificial intelligence (AI) and Internet of Things (IoT) technologies. By 2025, the global food automation market is expected to reach a value of $8.98 billion, with projections indicating growth to $12.2 billion by 2033, reflecting a compound annual growth rate (CAGR) of 3.9%. Similarly, the AI packaging market is anticipated to increase from $2.4 billion in 2024 to $6.2 billion by 2034, showcasing a remarkable CAGR of 10.1%. These trends underline the significant role of AI in transforming efficiency and sustainability within supply chains.

Tips: To effectively utilize AI in your packaging operations, consider integrating IoT sensors for real-time data collection. This will enable your business to optimize processes and enhance supply chain transparency. Additionally, exploring sustainable packaging solutions not only improves your environmental footprint but also responds to the increasing consumer demand for eco-friendly practices. Leverage the latest advancements in AI-driven testing and quality assurance to keep your products ahead of the competition.

The Future of Automated Packaging: AI Impact on Efficiency and Sustainability

Case Studies: Successful Implementation of AI in Packaging Across Industries

The implementation of AI in packaging has yielded remarkable results across various industries. One notable case is in the food sector, where a leading company adopted AI-driven robotic systems to automate packaging lines. By utilizing machine learning algorithms, the system optimized the packaging process in real-time, reducing waste and enhancing accuracy. This not only improved the speed of operations but also ensured that packaging materials were used more efficiently, leading to significant cost savings and reduced environmental impact.

Another compelling example comes from the pharmaceutical industry. A major drug manufacturer integrated AI for quality control during the packaging process. The AI system employs computer vision technology to detect defects and ensure compliance with strict regulatory standards. By automating these checks, the company minimized the risk of recalls and ensured higher safety for consumers. The implementation of AI not only streamlined their packaging processes but also bolstered the company's commitment to sustainability by reducing the amount of resources needed for quality inspections. These case studies highlight how AI is transforming the packaging landscape, driving both efficiency and sustainable practices in supply chains.

The Future of Automated Packaging: How AI Is Revolutionizing Efficiency and Sustainability in Supply Chains

| Industry | AI Application | Efficiency Improvement (%) | Sustainability Impact | Case Study Highlights |

|---|---|---|---|---|

| Food & Beverage | Predictive Maintenance | 25 | Reduced waste by 30% | Real-time monitoring of equipment health led to timely interventions. |

| Electronics | Automated Packaging Lines | 40 | Lowered carbon footprint by 15% | Increased throughput with minimal disruptions and optimized resource use. |

| Cosmetics | Smart Inventory Management | 30 | Enhanced recycling efficiency | Used AI to forecast demand, optimizing stock levels and reducing excess packaging. |

| Pharmaceuticals | Quality Control Automation | 20 | Improved safety compliance by 35% | Integrated AI for real-time detection of packaging errors, ensuring product integrity. |

Future Projections: How AI Will Shape the Next Generation of Supply Chain Management

The integration of artificial intelligence (AI) in supply chain management is expected to reshape the future landscape significantly. According to a report by McKinsey, companies implementing AI in their operations can achieve a 20-30% reduction in supply chain costs due to enhanced efficiency and optimized processes. One of the most promising areas where AI will have a profound impact is automated packaging. By leveraging machine learning algorithms, businesses can streamline packaging processes, reduce material waste, and enhance product protection during transit.

Furthermore, a study by Gartner reveals that by 2025, 75% of organizations will integrate AI into their supply chain operations, enabling real-time decision-making and greater demand forecasting accuracy. This shift towards AI-driven automation not only boosts efficiency but also plays a crucial role in sustainability. For instance, AI systems can analyze packaging materials and recommend more eco-friendly alternatives, contributing to reduced carbon footprints. As AI technologies continue to evolve, they will not only optimize packaging logistics but also support the broader goals of environmental conservation and sustainability within supply chains.

Related Posts

-

Top Automated Packaging Solutions That Transform Your Supply Chain Efficiency

-

Advantages of Embracing Automated Packaging Solutions for Global Supply Chains

-

7 Reasons Why Best Automated Packaging Solutions Will Transform Your Business in 2023

-

Ultimate Guide to Mastering Automated Packaging Strategies for Your Business

-

Future of Industrial Filling Machines Market Analysis for Global Buyers in 2025

-

7 Innovative Ways Automated Packaging Transforms Your Business Efficiency