The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Comprehensive Handbook for Sourcing the Best Industrial Filling Machines Globally

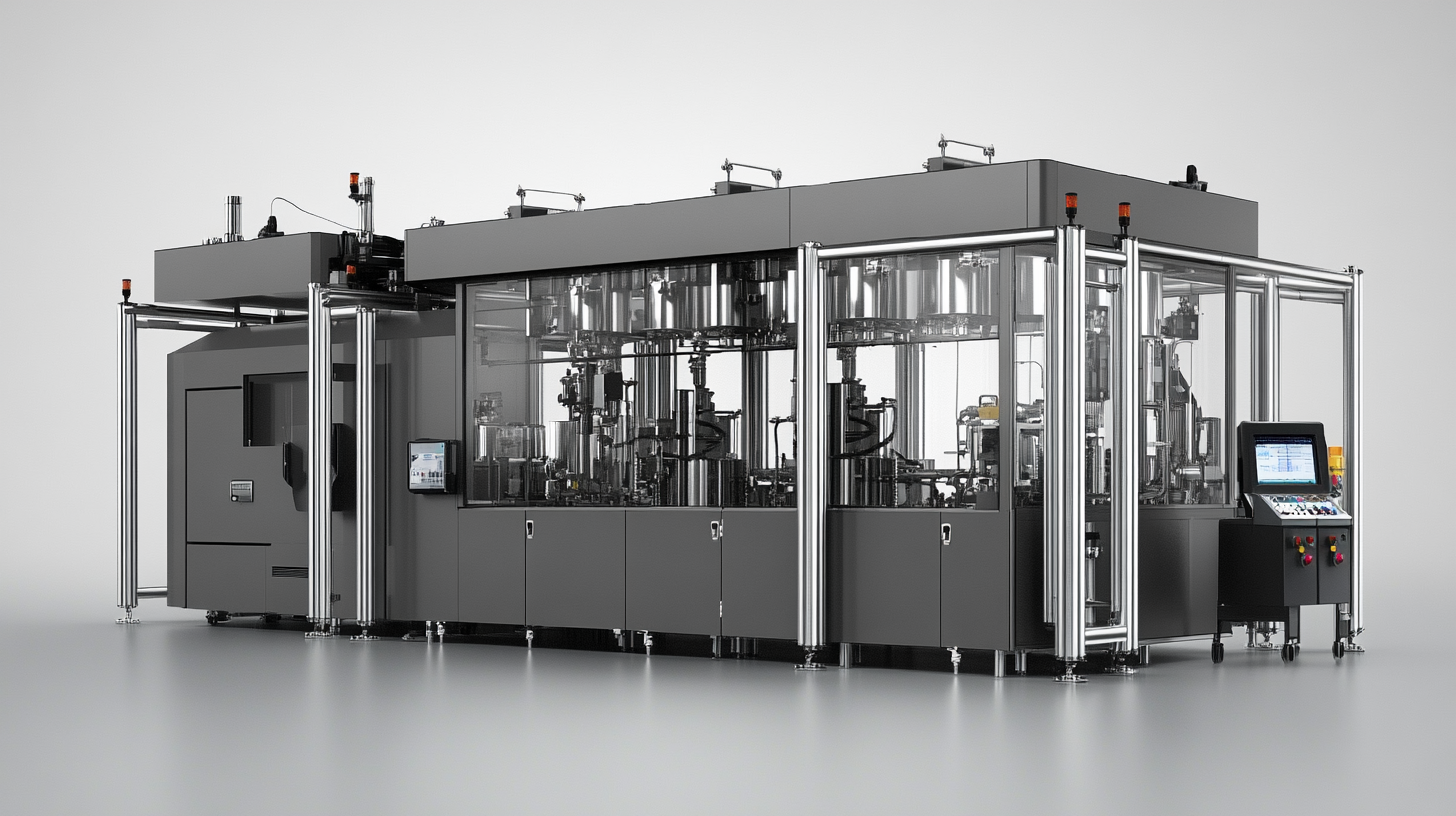

A machine for industrial filling remains an integral part of this advancement in modern manufacturing because it caters to the efficiency and accuracy of production processes. With these machines, concrete automation can be formed in the filling of all industrial products from food and drinks to pharmaceuticals. There are a lot of companies around the world, so it is quiet difficult for any organization to choose an industrial filling machine. This comprehensive guide will help to navigate through essential considerations, features, and best practices for sourcing the most suitable machines in filling operations.

For such companies seeking to optimize production lines with an overall enhancement in productivity, a thorough understanding of industrial filling machines is pertinent. The right choice can result in vast efficiency, consistency, and product quality improvements; while poor selection often leads to downtime costs and operational inefficiencies. This blog illustrates the models of types of industrial filling machines, important points to consider when sourcing, and ways to evaluate among suppliers to ensure that you invest in the best solution according to your unique needs. Join us on an expedition through the world of industrial filling machines and unleash the power of streamlined manufacturing processes.

Understanding the Types of Industrial Filling Machines Available Worldwide

The growth of filling machines for industrial purposes has seen considerable momentum due in part to consumer demand for packaged goods and advancements in filling technology. Filling machines come in many types; broadly, they can be divided into automation levels of either fully-automatic or semi-automatic. Fully-automatic filling machines are ruling the market due to their efficiency and precision, best suited for high-volume production lines; and semi-automatic ones preferred by small enterprises thirsting for flexibility and cost. The product type is analyzed; the market segments further down into different packing materials-glass, plastic, Tetra Pak, and cartons. Each of those materials presents its peculiarities and requirements for filling processes. Just to illustrate, glass filling machines cater most closely to the beverage industry, where preserving product quality and preventing contamination become paramount. In contrast, plastic and Tetra Pack solutions are gaining popularity due to their lightweight and recyclable nature, which appeals to environmentally conscious consumers. The methods of filling used by the machines are yet another component of market differentiation. Various filling techniques, such as vacuum filling, volumetric filling, and weight filling, are used for specific products to ensure their efficient and accurate packing. In particular, the automatic liquid filling machine sector is predicted to flourish between 2025 and 2032 due to technological advancements and increased investment into automation across several industries. The market size, share, and geographical insight show the fill operation's dynamic character in the industrial filling machine market cut out due to its crucial role in the packaging industry.

Key Factors to Consider When Sourcing Filling Machines Globally

The business has to consider many aspects when making international sources of filling machines. Most importantly, it should define the precise need of the application. The specificity of the filling machine requirements lies in its industry, which could be pharmaceuticals, food and beverage, or cosmetics. These demand the machines to have some peculiarities in the filling precision and material handling. Hence, understanding what the product being filled, its viscosity, and packaging type would very much guide the selection process.

The next point would be assessing the kind of technology that would be expected of the machines. Flexibility rules: if it is coupled with the fortuitous installation in line with speed and precision, then he is going to be very productive. For that reason, automatic adjustment-ready, connectivity options for data tracking, and process optimization could be observed in the purchase consideration. It is also important to check the compatibility of the machine to the current production lines because compatibility will minimize possible downtime and make the process less costly.

However, supplier reliability and support services are critical factors in making a decision. To source machine supplies from around the world, what do they think about reputation and customer feedback, including that of after-sales support? A good relationship between suppliers will ensure there is prompt maintenance and accessibility to spare parts, crucial in reducing production stoppages. Caring for all these aspects will lay a proper foundation for a successful sourcing exercise.

Top Manufacturers of Industrial Filling Machines and Their Offerings

The industrial filling machine market remains in a state of transition, currently experiencing increased momentum, which has become evident due to advanced improvements in the production processes and the adoption of Industry 4.0. With the growing global market share of liquid filling machines, major manufacturers are targeting different functional types like fully automatic and semi-automatic systems. The surge in demand for these machines across various sectors such as food and beverage, cosmetics, and pharmaceuticals would cause industries to demand extra efficiency and precision.

Each product type has, in its own right, been a dominating factor in the filling machine market, including glass, plastic, TETRA packaging, and carton box options. Each type caters to unique requirements to provide customized solutions for their clients. Meanwhile, the application of various filling types-co vacuum filling, volumetric filling, and weighing filling-must follow on the heels of optimizing one more production process. Among other things, ergonomics, serviceability, and scalability weigh heavily on the mind of businessmen when considering the type of filling machines to buy.

Lately, manufacturers have enhanced their offering by introducing advanced features such as automated cleaning systems and other sealing technologies, vital in keeping packaging quality standards with safety regulations. The possibility of additional growth in the liquid filling machine industry seems bright and provides a bright prospect for this important industrial equipment as further innovations and changes in production lines are undertaken by companies such as international players.

The Role of Technology in Enhancing Filling Machine Efficiency

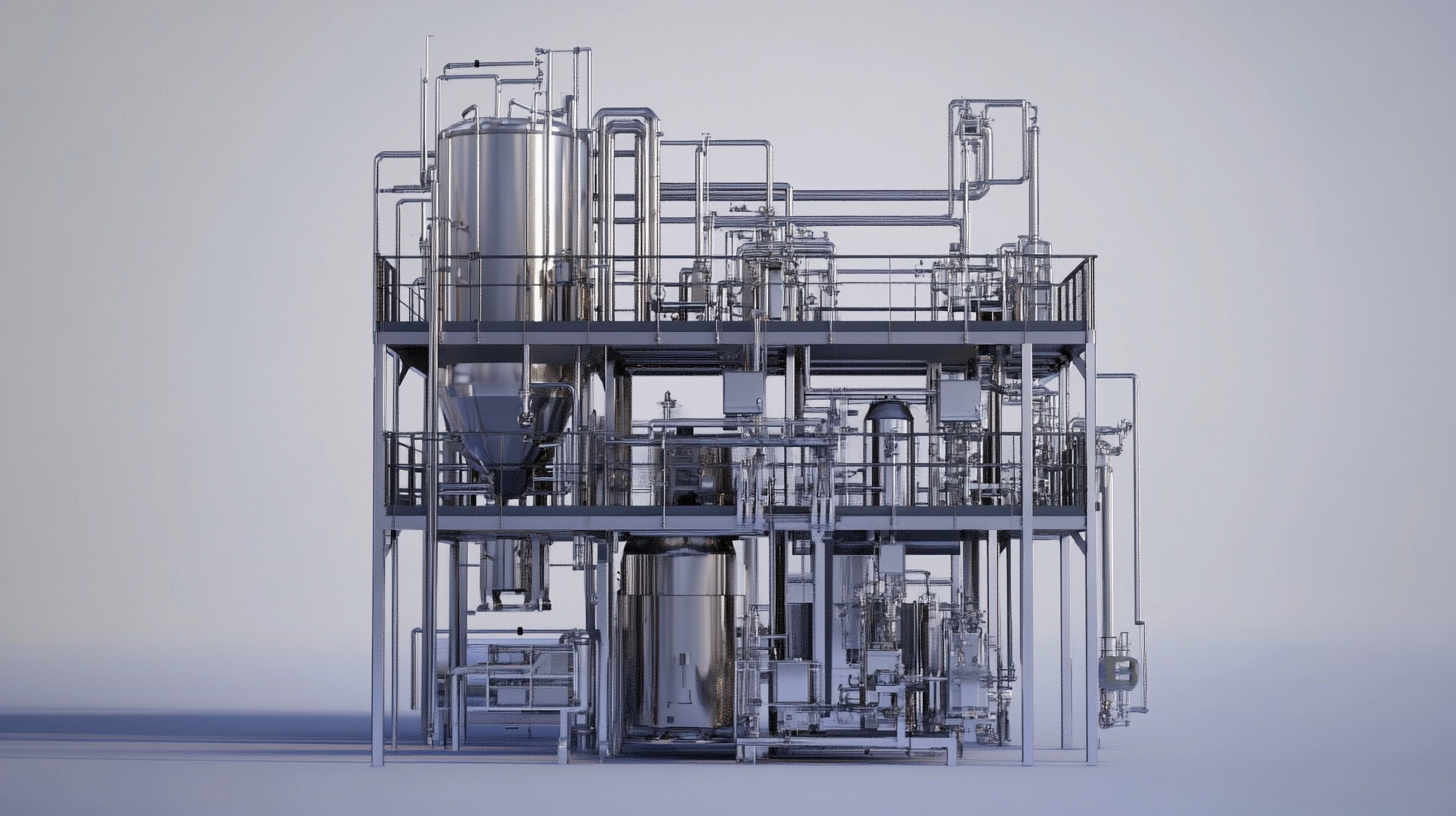

Modern innovations contribute significantly to the changing features in the global liquid filling machine market. It is, therefore, apparent that novel solutions creating efficiency and optimizing production processes have triggered a massive growth in the market from $6.82 billion in 2025 to an astounding $10.39 billion in 2032 at a standard CAGR of 6.2%. Smart technology integration and IoT systems can improve manufacturers' operational capabilities, enhance workflow, and minimize downtime.

The automation, in particular, is accentuating the filling capacity of the filling machines. Sophisticated sensors and data analytics have brought about the ability of companies to monitor and control the filling process in real-time, thus ensuring accuracy and stability. This leads to less wastage and faster changes to production needs. Given the ever-increasing need for cost-efficient and reliable manufacturing solutions, the focus on technologically advanced filling machines will have a major impact on market dynamics.

Increasingly, the industrial filling machine of the future is also being shaped by a growing focus on sustainability. Newer machines are being designed to use energy efficiently on one hand while processing at high speeds. An impetus on eco-friendly practices accompanied by higher efficiency, courtesy of technology, fits neatly into the changing needs of manufacturers who want productivity and sustainability.

Best Practices for Comparing and Selecting Filling Machines for Your Needs

Today, there is so much information available regarding the best filling machines for different industries. Firstly, you need to understand the different types of filling machines available in the market. Different categories of filling machines, such as gravity fillers, pressure fillers, and vacuum fillers, are designed to cater for certain product properties and requirements. Analyze the product viscosity, possible container sizes, and production speed before narrowing down your options to the machines that best suit the operational goals.

Secondly, you have to look at the technology and features offered by filling machines. Modern filling machines are equipped with advanced technologies improving efficiency and precision. Features such as automatic adjustment for different container sizes, easy cleaning, and safety should be looked up in purchasing. This leaves comparative analysis of the specifications above to take you a step further in choosing a machine that is within the industry standards but also improves your overall productivity.

You also want to pay attention to support and services provided by manufacturers. Remember, a machine is as good as the support you can get when something goes wrong. Put your time into researching brands known to have excellent customer service and are offering long-term support agreements in order to avoid potential downtimes in future. These are the best-practices when comparing filling machines so that your business can have a competitive edge in the industry.