The Duravant family of operating companies serve the food processing, packaging and material handling segments.

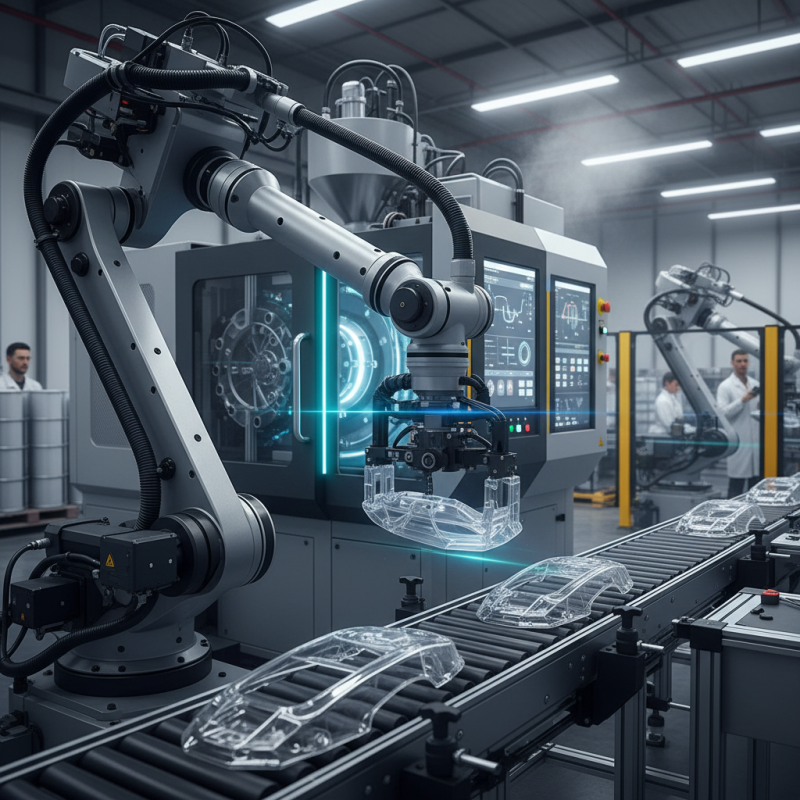

What is an Injection Machine Robot and How Does It Work?

The injection molding industry is rapidly evolving. Automation is on the rise, and Injection Machine Robots are at the forefront of this transformation. According to a recent report by Market Research Future, the global injection molding machine market is projected to reach USD 15 billion by 2027. This indicates a growing reliance on automation for production efficiency and cost reduction.

Injection Machine Robots streamline various processes in manufacturing. They handle tasks like loading, unloading, and part finishing, ensuring precision and speed. However, despite advancements, challenges remain. Many companies struggle with integration and maintenance of these robotic systems. The initial investment for automation can be high, and not every operation sees immediate ROI.

Organizations must weigh the pros and cons of adopting Injection Machine Robots carefully. While these machines promise improved productivity, issues such as technical complexity and workforce retraining need attention. A well-thought-out approach is essential to harness their full potential in the manufacturing landscape.

What is an Injection Machine Robot?

An injection machine robot is a specialized device used in manufacturing. It automates the process of injecting materials, typically plastics, into molds. This robot ensures precision and efficiency. It works by heating the material until it melts and then injecting it into a mold. Once the material cools, it takes the shape of the mold. This process is fast and repeatable.

These robots greatly enhance production speed. They can operate continuously, reducing the need for human intervention. However, not every setup is perfect. Sometimes, the material may not flow correctly. Inconsistent temperatures can lead to defects in the final product. Operators often need to monitor the process closely. Regular maintenance is crucial for optimal performance, yet, it's often overlooked. This can lead to unexpected downtime.

In conclusion, an injection machine robot serves a vital role in modern manufacturing. While it delivers efficiency, challenges remain. A well-trained team is essential to ensure that this technology runs smoothly. Understanding both its capabilities and limitations is key to success.

The Components of an Injection Machine Robot

Injection machine robots play a crucial role in modern manufacturing. They automate the injection molding process. This process creates parts from various materials like plastic. Understanding the components of these robots is key to grasping their functionality.

The main components include the robotic arm, injection unit, and control system. The robotic arm is responsible for precise movement. It operates with hydraulics or electric power. This allows it to move quickly and accurately. The injection unit melts the material and injects it into molds. Finally, the control system coordinates the entire process.

Tip: Regular maintenance of the injection machine robot is vital. This ensures optimal performance and prolongs its lifespan.

Robotic arms often have sensors for feedback. They can adjust their movements based on real-time data. However, they do require careful programming. Mistakes in programming can lead to inefficient operations.

Tip: Always test new programs in a safe environment. This minimizes potential risks during production.

Each component contributes to the overall efficiency of the injection machine robot. Understanding the relationship between these parts enhances troubleshooting efforts. But, complexities may arise, demanding ongoing training and learning.

The Working Principles of Injection Machine Robots

Injection machine robots are integral to modern manufacturing. Their design allows for efficiency and precision in the injection molding process. These robots automate the placement, extraction, and handling of products within injection molding machines. According to a recent industry report by MarketsandMarkets, the injection molding machine market is projected to grow to $16.8 billion by 2025. This growth underscores the importance of automation and robotics in enhancing productivity.

The working principles of these robots rely on advanced programming and sensor technology. They operate through a series of coordinated movements, transporting materials from one station to another. They often employ servo motors for increased speed and accuracy. Research shows that robots can reduce labor costs by up to 30% while also minimizing production defects.

However, there's an ongoing challenge in balancing automation with human oversight. Not all factories have embraced this technology entirely. Fear of job loss and high initial investment costs can hinder implementation. Moreover, many companies still rely on manual methods for certain tasks. This could be due to the complexity of existing systems or lack of trained personnel.

It's worth noting that implementing robotic systems requires substantial training and adjustment. Transitioning to a fully automated process is not an overnight task. With diligence and thoughtful planning, companies can improve their output and quality.

Applications of Injection Machine Robots in Industry

Injection machine robots play a crucial role in modern manufacturing. These robots assist in automating the injection molding process. According to a report from Markets and Markets, the global injection molding machine market is expected to reach $16.68 billion by 2025, highlighting the increasing relevance of these technologies in production.

In the automotive sector, injection machine robots are essential for creating parts with precision. They significantly reduce waste and improve efficiency. A study by Grand View Research shows that the use of robots can increase production rates by up to 25%. However, the integration can face challenges. Companies must train staff to understand robotic systems, which can be complex.

Furthermore, in the consumer goods industry, these robots help in producing items like containers and packaging with high accuracy. Despite their advantages, not all businesses can easily adopt this technology. The initial investment remains a barrier for many smaller manufacturers. Therefore, assessing long-term benefits against upfront costs is vital for decision-makers.

Applications of Injection Machine Robots in Industry

Advantages of Using Injection Machine Robots in Manufacturing

Injection machine robots are transforming manufacturing. They automate the process of injecting materials into molds, leading to increased efficiency. Labor costs decrease with machines taking on repetitive tasks.

One significant advantage is precision. Robots consistently perform tasks with high accuracy, minimizing fluctuations in quality. This not only improves products but also boosts customer satisfaction. Companies can meet tighter tolerances more easily, making them competitive.

Tip: Regular maintenance of these machines is crucial. A well-maintained robot reduces downtime. Also, provide training for staff to enhance their handling skills.

Despite their benefits, some challenges exist. Initial costs for setup can be high. Not every factory needs full automation; it requires careful evaluation. Companies must reflect on their specific needs before making a switch.