The Duravant family of operating companies serve the food processing, packaging and material handling segments.

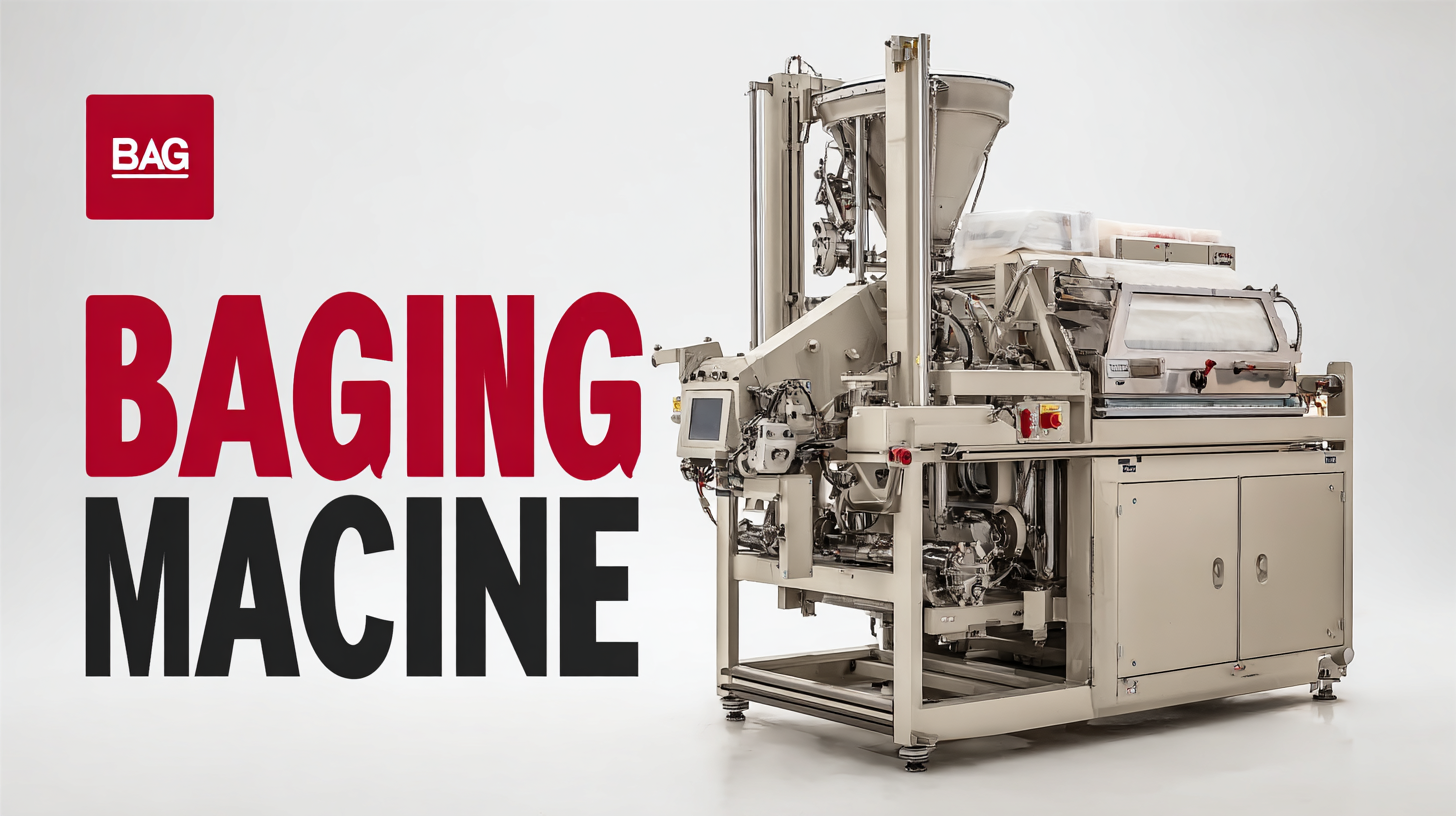

Leading the World in Industrial Bagging Machine Manufacturing Excellence

In the ever-evolving landscape of manufacturing, the significance of achieving excellence in industrial bagging machine production cannot be overstated. As the industry becomes increasingly globalized, the demand for high-quality, efficient, and reliable bagging solutions has surged, prompting manufacturers to seek ways to enhance their processes and certifications. One of the crucial aspects influencing this pursuit is compliance with international import and export standards, which serve as benchmarks for quality and reliability. By leading the world in the manufacturing of industrial bagging machines, companies not only elevate their own operational capabilities but also fulfill the rigorous requirements set forth by global regulatory bodies.

This drive for certification not only ensures that products meet safety and performance standards but also fosters trust and credibility in international markets, paving the way for sustained success in the competitive arena of bagging technology.

Revolutionizing Packaging: The Impact of Industrial Bagging Machines on Global Supply Chains

The global packaging landscape is undergoing a transformative evolution, particularly with the rise of industrial bagging machines. According to a recent market research study, the global pharmaceutical plastic packaging market is projected to reach USD 681.33 billion by 2034, growing at a remarkable CAGR of 16.39%. This surge is indicative of the vital role packaging technology plays in enhancing the efficiency and reliability of supply chains worldwide.

As companies strive to meet increasing consumer demands, innovations like automated packaging solutions are becoming crucial. The logistics and supply chain industry is experiencing significant shifts, aided by AI and machine learning applications that can reduce logistics costs by 15%, inventory levels by 35%, and improve service levels by 65%. Such advancements not only streamline operations but also significantly contribute to sustainability efforts within organizations.

Tip: To stay competitive, businesses should consider investing in automated packaging technologies. These solutions not only enhance operational efficiency but also ensure that companies can adapt quickly to the evolving demands of e-commerce and global supply chains. Keeping an eye on industry trends will help businesses leverage these innovations effectively and maintain a cutting-edge position in the market.

Market Insights: Growth Trends in the Industrial Bagging Machine Sector for 2023

The industrial bagging machine sector is witnessing significant growth, aligning with broader market trends in packaging machinery. In 2019, the global packaging machinery market was valued at approximately $42.13 billion, and projections indicate an increase to $70.23 billion by 2032, reflecting a compound annual growth rate (CAGR) of 2.4%. This trend is driven by rising demand for efficient packaging solutions across various industries, including food, pharmaceuticals, and chemicals.

As we look toward 2023 and beyond, it’s essential for stakeholders in the industrial bagging market to recognize key growth factors. According to recent market insights, the global freeze-drying equipment market is anticipated to reach $2.08 billion in 2023, expanding to $3.83 billion by 2032, which highlights a growing trend in specialized packaging solutions. Additionally, the liquid filling machine market is expected to grow from $6.82 billion in 2025 to $10.39 billion by 2032, showcasing an annual growth rate of 6.2%.

**Tips:** When investing in industrial bagging equipment, consider the increasing demand for automation and efficiency. Additionally, keep an eye on regional market trends, especially in emerging markets like Southeast Asia, which is becoming a hub for packaging innovations. Understanding these dynamics can provide strategic advantages in a competitive landscape.

Leading the World in Industrial Bagging Machine Manufacturing Excellence - Market Insights: Growth Trends in the Industrial Bagging Machine Sector for 2023

| Region | Market Size (USD Million) | Growth Rate (%) | Key Trends |

|---|---|---|---|

| North America | 250 | 5.2 | Automation and Smart Features |

| Europe | 300 | 4.8 | Sustainability Initiatives |

| Asia-Pacific | 500 | 6.5 | Rapid Industrialization |

| Latin America | 150 | 3.9 | Emerging Markets |

| Middle East & Africa | 100 | 4.0 | Infrastructure Development |

Sustainable Solutions: Eco-Friendly Innovations in Bagging Technology

As the demand for sustainable solutions in packaging continues to rise, innovations in bagging technology are paramount. Companies are increasingly recognizing that consumers prioritize eco-friendliness along with quality and durability, with many willing to invest in long-lasting products. This shift in consumer expectations is not only reshaping the consumer durables market but also driving advancements in industrial bagging machine manufacturing.

To align with these trends, manufacturers are leveraging eco-friendly materials and smart technology to create efficient and sustainable packaging solutions. The integration of such innovations facilitates not only better environmental practices but also enhances the overall reliability of the packaging. Tips for businesses looking to adopt sustainable bagging solutions include sourcing biodegradable materials, optimizing packaging sizes to minimize waste, and investing in high-speed auto bagging systems that reduce energy consumption.

Moreover, showcasing fresh innovations, companies are displaying their latest efforts at industry events, offering live demonstrations that highlight advancements in eco-friendly packaging. Engaging with these trends is crucial for maintaining a competitive edge in the market, as the urgency for sustainable practices becomes more pronounced among consumers.

Maximizing Efficiency: Key Performance Metrics for Modern Bagging Machines

In today's competitive landscape, modern bagging machines play a pivotal role in maximizing efficiency across various industries. Focused on key performance metrics, it’s essential to prioritize factors such as speed, accuracy, and energy consumption. These machines are not just about filling and sealing bags; they embody a comprehensive system designed to streamline the packaging process while reducing operational costs.

Tips for enhancing the efficiency of your bagging machines include periodic maintenance to prevent downtime, leveraging automation technology to minimize human error, and conducting regular performance audits to identify bottlenecks in the workflow. Additionally, considering energy-efficient features in machinery can lead to significant cost savings over time.

Aligning your bagging operations with industry trends—such as those highlighted in the advancements seen in tea processing and rice milling—can further boost productivity. Embracing modern technology ensures that the equipment meets the demands for precision and sustainability, helping organizations stay ahead in a rapidly evolving market.

Case Studies: Successful Implementations of Bagging Solutions Across Industries

In the ever-evolving landscape of industrial technology, bagging solutions have emerged as critical tools for enhancing efficiency across various sectors. In our recent case studies, we have highlighted successful implementations of our bagging machines in diverse industries, showcasing how they streamline operations and improve productivity. From agriculture to manufacturing, these tailored solutions adapt seamlessly to different materials and processes, ensuring optimal performance and reliability.

The recent 3rd Shanghai Carbon Expo exemplifies the global shift towards innovation and sustainability, particularly with the introduction of new exhibition areas highlighting cutting-edge technologies. As companies seek to improve their operational efficiencies while adhering to environmental standards, the demand for advanced bagging solutions continues to grow. These case studies serve as testament to how our high-quality bagging machines are not only leading the industry but also supporting businesses in achieving their sustainability goals through reduced waste and improved resource management.