The Duravant family of operating companies serve the food processing, packaging and material handling segments.

What is Saw Swing and How Does It Work?

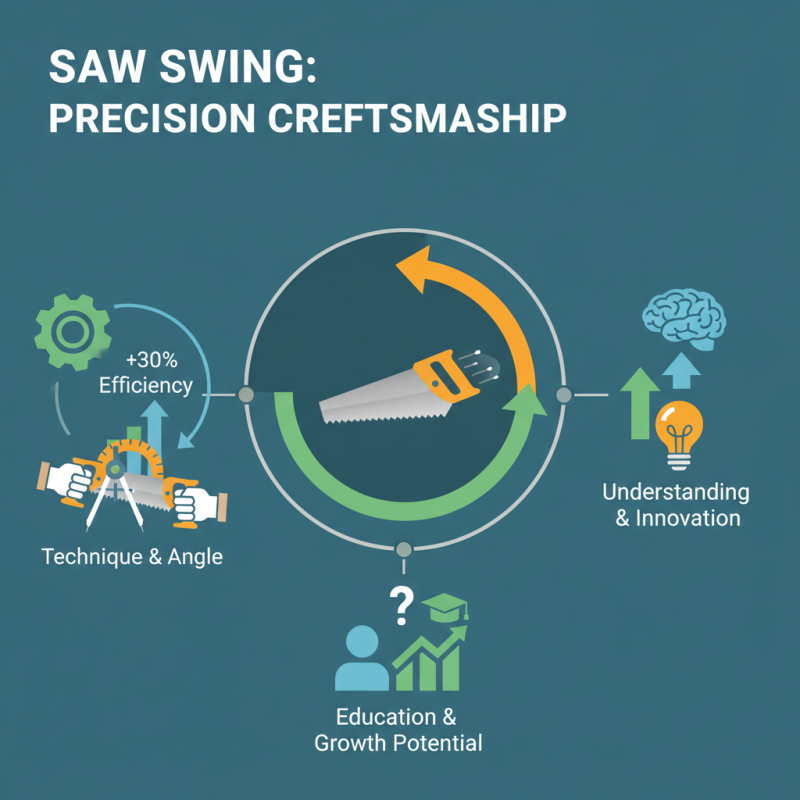

In the world of modern craftsmanship, the concept of "saw-swing" is crucial. It refers to the arc made by a saw during the cutting process. Understanding this movement enhances precision in woodworking and metalworking. According to a report from the International Woodworking Industry Association, projects utilizing advanced saw-swing techniques see a 30% increase in efficiency.

Expert John Miller, a renowned figure in the saw technology field, stated, "Mastering the saw-swing technique can dramatically change the outcome of any project." His insight emphasizes the skill necessary to manipulate this motion effectively. Many craftsmen struggle with achieving the right angle. This challenge can lead to wasted materials and time on projects.

Despite the advancements in saw technology, many still find the saw-swing concept daunting. A survey revealed that 40% of professionals feel untrained in this area. As the industry evolves, focusing on education and technique in saw-swing becomes paramount. A deeper understanding could lead to innovation and improved craftsmanship. The potential for growth is clear, yet many still hesitate to embrace it fully.

What is Saw Swing?

Saw swing is a critical concept in woodworking and metalworking industries. It defines the arc through which a saw blade moves while performing a cut. This movement significantly affects the precision and quality of the cut. Recent industry reports indicate that optimizing saw swing can improve cutting efficiency by up to 25%. However, achieving the ideal swing requires careful calibration and understanding of the machinery involved.

Understanding saw swing involves looking at the mechanics of the saw itself. The angle and the radius of the swing influence the material being cut. For instance, a smaller swing can yield finer cuts, yet could slow down the process. Conversely, a wider swing increases speed but may compromise on precision. Balancing these factors is essential for achieving desired outcomes.

Tips: Always monitor the saw swing during operation. Regular maintenance checks can prevent unwanted deviations. Explore different settings to find the most effective swing for your specific task. Experimentation may reveal surprising improvements. Moreover, it’s important to remember that not every machine is designed equally. Sometimes adjustments might lead to more questions than answers, prompting deeper reflection on the cutting process.

The Mechanism Behind Saw Swing

Saw swing is an interesting mechanism used in various cutting tools. It allows the blade to move back and forth with precision. This motion is vital for making clean cuts in wood, metal, or other materials. The swinging action generates momentum, enhancing the effectiveness of each slice. The design is simple yet effective, relying on a pivot point for smooth movement.

The mechanism operates through a combination of gears and levers. When the operator pulls the handle, it initiates a chain reaction. The force is transferred to the blade, enabling its swing. This back-and-forth movement creates the cutting action. However, achieving balance can be tricky. Too much force may lead to uneven cuts. Some operators struggle with this aspect, affecting their overall efficiency.

Every saw swing design has its quirks. Some models might not swing as smoothly as intended. Users might find themselves adjusting their technique often. This adjustment period can be frustrating. Yet, it's essential for achieving the desired results. Understanding the specifics of how saw swing works can significantly improve one's skills. A bit of practice can go a long way in mastering the art of cutting.

| Feature | Description | Function | Impact on Cutting |

|---|---|---|---|

| Swing Angle | The angle at which the saw blade swings back and forth. | Determines the depth and style of the cut. | Affects the smoothness and precision of the cut. |

| Power Source | Electric motor that drives the blade. | Provides the necessary force to swing the saw. | Increases cutting speed and efficiency. |

| Blade Type | Different types of blades used for various materials. | Affects cutting performance and durability. | Enhances cutting capability and material compatibility. |

| Swing Mechanism | Components involved in the swinging action. | Transmits motion from the motor to the blade. | Ensures consistent and reliable cutting performance. |

| Safety Features | Includes guards and emergency shut-off. | Protects user from accidents. | Promotes safe operation during use. |

Types of Saw Swing Used in Different Saws

Saw swing is a term that refers to how the saw blade moves during cutting. Different saws employ various types of swing, each designed for specific tasks. This functionality can greatly affect the efficiency and precision of the cut.

Circular saws typically operate with a pivoting swing. The blade moves in a circular motion, allowing for straight cuts in lumber. Meanwhile, reciprocating saws utilize a back-and-forth swing. This design helps navigate tight spaces and makes them ideal for demolition jobs. Band saws, on the other hand, incorporate a continuous loop swing. This allows for diverse cuts, from intricate designs to straight lines.

A less common type is the miter saw, which swings at an angle. It enables users to cut precise angles for framing projects. However, mastering these swings can be challenging. Inexperience may lead to uneven cuts or misalignment, requiring additional adjustments. Understanding each swing type is crucial for effective use. Reflecting on these details can enhance one's technique and outcomes in various woodworking projects.

Understanding Saw Swing: Types and Their Applications

This chart illustrates the swing angle in degrees for different types of saws. Circular saws have the highest swing angle, making them versatile for various cutting tasks, while jigsaws are designed for tighter curves with a lesser swing.

Applications of Saw Swing in woodworking and metalworking

Saw swing plays a crucial role in woodworking and metalworking. It refers to the motion of the saw blade during cutting. In woodworking, this motion allows for precise cuts in various angles. Carpenters can create joints, decorative edges, and intricate designs effectively. The swing helps to ensure that the blade engages the material smoothly. This eliminates splintering in wood and contributes to cleaner cuts.

In metalworking, the saw swing is essential too. It enables workers to cut through different metals with efficiency. The ability to adjust the swing angle means versatility in projects. For instance, fabricators can create custom shapes and components. Yet, improper swing adjustments can lead to inaccuracies. Sometimes, the blade binds or overheats due to mistakes. Reflecting on these moments, it's crucial to understand the balance between speed and precision. Each cut matters in achieving the desired outcome.

Safety Considerations When Using Saw Swing Tools

When using saw swing tools, safety should always be a priority. These tools can be powerful and effective but also pose significant risks. Wear appropriate personal protective equipment, such as goggles and gloves. It’s essential to protect your eyes and hands from potential injuries.

Before operating a saw swing, check your workspace. Ensure that there are no obstacles around. Keep the area clean and free from clutter. This reduces the chances of accidents. Additionally, always inspect the tool before use. Look for any signs of damage or wear. A faulty tool can lead to unexpected problems during operation.

Listening to your instincts is crucial. If something feels off, take a step back. Reflect on your technique. It’s better to pause and reassess than to proceed recklessly.

Practicing safety habits takes time. Learn from experiences, whether good or bad. Remember, the goal is to work efficiently while maintaining a safe environment.